SCCRWA Remote Sites Project Upgrade

(Greater New Haven Area Pump Stations)

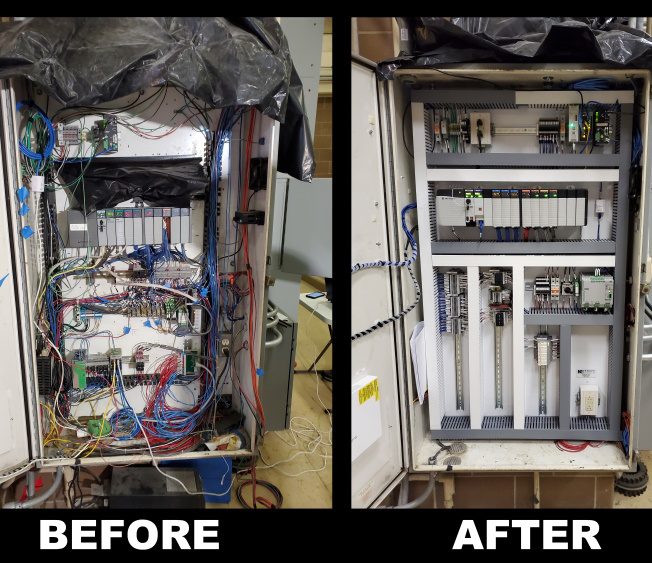

- Upgrade of 90+ remote sites in the Greater New Haven region including pump stations, tanks, well fields, throttling valve and pressure reducing valve sites

- Provided new control panels, field surveys, field wiring, electrical services, trenching, fiberoptic network upgrades, retrofitting of existing panels, demolition, etc.

- Preliminary cellular radio testing, installation and testing of new cellular radio and antenna systems

- Retrofitting control panels while maintaining stations online presence

- Collaborative work efforts with RWA, EES, and EMA to efficiently and successfully transition remote sites and upgrade SCADA to the latest technology of PLC’s and software

- Offered end used more water usage and supply efficiency, and more streamlined data collection for each remote site

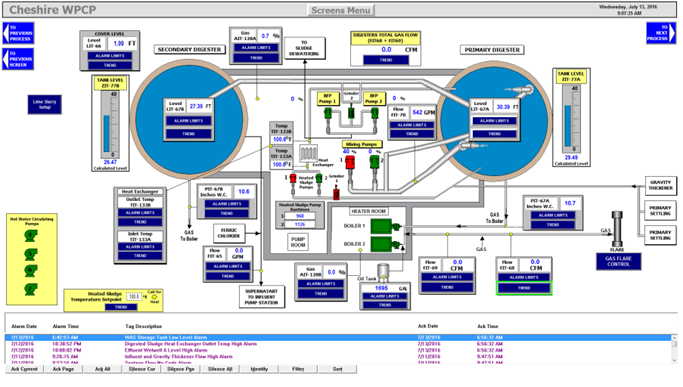

Cheshire WPCP

Water Pollution Control Plant (WPCP) Upgrade

- Complete SCADA Upgrade of the Town of Cheshire’s Water Pollution Control Plant

- 12 UL Listed Instrumentation and Control Panels

- New Redundant Ethernet/Fiber Optic Network to Transmit Data to Centralized SCADA Server Cabinet

- 10 Personal Computer Workstations

- Daily & Monthly Historical Data Reports

- WIN-911 Alarming Software Configuration

- Plant Operations Maintained Throughout Upgrade

- Seamless Integration of New SCADA System

West Haven WPCF

Water Pollution Control Facility (WPCF) Upgrade

- SCADA Upgrade of the City of West Haven’s Water Pollution Control Facility

- Upgrade of the Following Processes:

– Aeration Control

– Headworks

– RAS Control

– WAS Control

– MLR Control

– Denitrification Process - Allen Bradley CompactLogix Processors

- New Industrial Ethernet & Fiber Optic Network

- New Server Cabinet for Monitoring & Control of Entire Plant Across Workstations

- Field Instruments Provided:

– Nitrate Analyzers

– pH Analyzers

– ORP (Oxidation-Reduction Potential) Analyzers

– DO (Dissolved Oxygen) Analyzers

– Thermal Mass Air Flow Meters

– Magnetic Flow Meters

– Level Transmitters

– Pressure Transmitters

– Temperature Transmitters

East Lyme/New London

Water Main Interconnection Project

- Interconnection Project to Bring Fresh Drinking Water to the Towns of East Lyme & New London

- Two Booster Pump Stations & Water Storage Tank Erected to Provide Water Between Towns

- Provided the Following Materials & Services:

-Four Radio Telemetry Control Panels

-One Analog Signal Splitter Control Panel

-pH & Chlorine Analyzers

-Venturi Flow Tube Installation & Differential Pressure Transmitters

-Magnetic Flowmeters & Gauge Pressure Tranmitters - Conducted Radio Path Surveys & Installed Licensed Radios

- New Radio System Providing Monitoring & Control Between Booster Pump Stations and Storage Tank

Lake Onondaga- Syracuse, NY

EPA Superfund Site – Onondaga Lake Cleanup

- Lake Onondaga is often Referred to as the Most Polluted Lake in America

- Fabricated Allen-Bradley Based PLC Control Panels which Included:

– Carbon Control Panel

– Make-Up Water Pump Control Panel

– Sand Slurry Control Panel - Supplied & Configured a SCADA Workstation Computer in the Onsite Remediation Trailer

- Carbon and Sand Slurry Mixture was Sent to a Barge to Cap the Bottom of the Lake

- Radio Communications Panel Installed to Communicate from the Onsite Trailer to the Barge: GPS Tracking Needed for Accurate Capping of Each Lane’s Specific Dump Requirements

J. L. Lucas Machinery Company, Inc.

Double Disc Grinding Machinery

- Design & Fabricate CNC (Computer Numeric Control) and Motion Controls for J. L. Lucas Machinery Co., Inc. for Over 20 Years

- J. L. Lucas Provides Remanufactured Disc Grinders for:

– Automotive

– Aerospace

– Railroad

– Windmill Parts

– Other Specialty Machines - We Provide the Following:

– Custom Control Panels

– Machine Wiring

– VFDs

-Start-up & Troubleshooting

-Programming Integration Using FANUC, Allen-Bradley, Siemens & Mitsubishi CNC/Motion Controllers - Design Controls that need to be UL508, CE, CSA. NFPA79 Machinery Standards

- Part Gauging is Usually Integrated into the Controls for Part Quality and Automatic Compensation to Keep Parts within Specifications

- Variety of VFDs Used for Main Rotation Equipment, Feeders, and Wheel Dressing Operations

- VFD’s Include GE, A-B, Fuji, Siemens

Various Industrial Projects and Service

- Provide Programmable Logic Controllers and Operator Interfaces for Plant Controls

- Program Operations for Flow Pacing and Batch Operations

- Connect PLC Nodes to Networks for Viewing in one Central Location

- Industrial Machinery Automation, Assembling, Automotive, Robotics

- Troubleshoot and Service Controls and Instruments in System

- Industrial Treatment Systems for Removal of Unwanted Wastes

- Service Machinery Controls and Retrofits